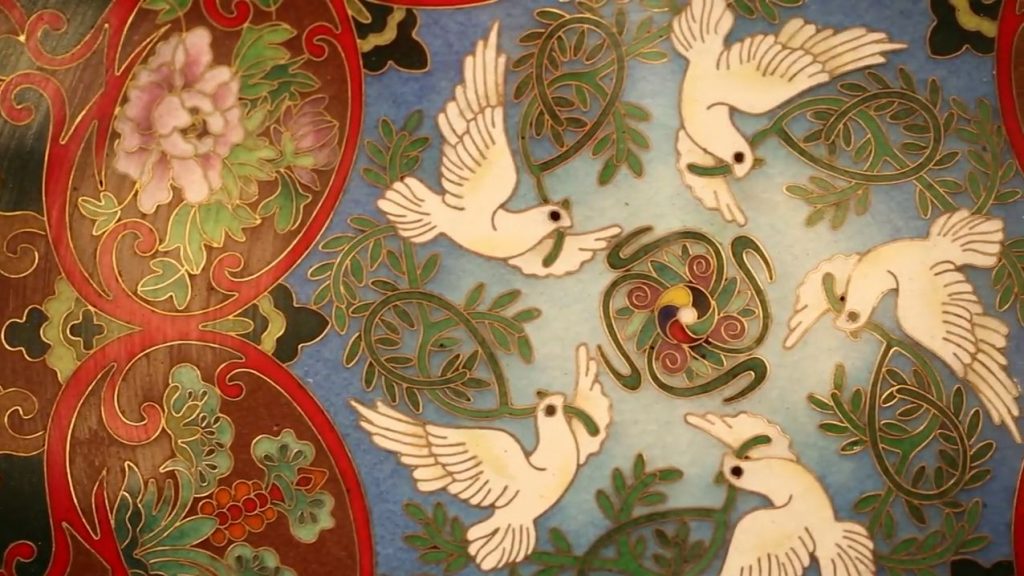

When you look at a baoding ball with elegant designs, you might wonder what kind of artwork this is. It is a technique called cloisonne (pronounced like cloy-son-aye). It is an art method dating as far back as the 14th century in China.

Cloisonne is the technique of creating designs on metal with enclosures of copper wires. These enclosures, called cloisons, are twisted and bent into various shapes which are then softly hammered, glued, and soldered onto the metal. Then the cloisons are filled with an enamel paint, fired, and polished revealing beautiful color.

Cloisonne is a National Treasure of China

It was first imported into China over 700 years ago from ancient Greece and Egypt. The technique was learned and developed during the Ming dynasty. It was a very time consuming and labor intensive processes with many steps so cloisonne items were only owned by the royal family. This raised the value and desirability of cloisonne greatly.

Cloisonne Designs Are All Hand Shaped

Once the metal piece has been prepared, artisans must bend and pinch copper wires into the specified designs. It is a skill that requires years of practice and patience as finishing one piece such as a vase or plate can take two months just for making and applying the copper wires. In modern day China, less people are doing this craft as a profession. Older generation masters are now teaching apprentices only one of the steps such as wire shaping or enamel painting instead of all the steps. Hoping to preserve and pass down the techniques in modern times, this way younger artisans become skilled faster and work more efficiently with others.

Next the copper shapes are dipped in a special glue and then arranged on the metal piece before going to the firing process.

After all the wire shapes are glued onto the piece, it is taken to be heated in a very hot kiln to 800 degrees Celsius. It is a small step, but each step is as important as the others because all other steps depend on the other work being done properly.

Cloisonne is Hand Painted and Polished

Painting each copper wire enclosure is the next step of the cloisonne process. A metal oxide powder is mixed with water to create the enamel paint. With over 3000 colors today, the options are much greater than ancient times and the craftsman has be be skilled at matching colors together. Instead of paint brushes, small tools and droppers and used to dab and fill in the areas with the enamel paint.

The pieces are fired in the kiln again melting the glaze adhering it to the copper wires and metal body. The process is repeated several times as colors and paint can burn or shrink during the firing. After painting is completed, the pieces are taken to be polished. This uses sanding and polishing compounds to smooth out any imperfections in the cloisonne.

After the several rounds of painting and sanding, a cloisonne piece is gold plated on the exposed copper areas. The end piece is a representation of an ancient art and treasure with beauty to last for years.

Cloisonne in the Palm of Your Hand

This technique was adapted in Baoding China for making cloisonne on metal balls. As cloisonne is a national treasure, cloisonne health balls are Baoding’s treasure. After hundreds of years, cloisonne is still be developed. Many cloisonne pieces now use resins and epoxy which imitate the look of cloisonne paint. It’s faster, lower cost, and more durable. As such, most painted baoding balls today use imitation cloisonne. Now you know when you hold a pair of baoding balls in your hand, you are holding something made by hand with hundreds of years of crafting history.